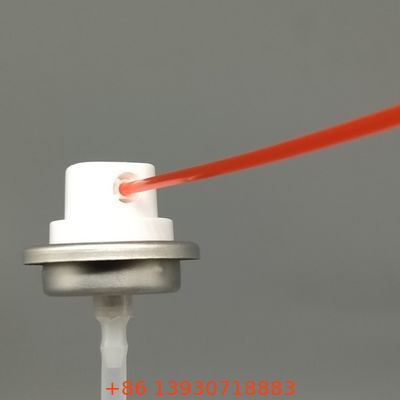

Heavy-Duty WD-40 Lubricant Valve for Construction and Mining Equipment with Corrosion-Resistant Construction and High-Pressure Performance

Built to withstand the most demanding industrial environments, our rugged WD-40 Lubricant Valve delivers reliable performance under extreme conditions. This industrial-strength corrosion-resistant valve features enhanced materials and construction specifically engineered for heavy machinery maintenance in construction, mining, and marine applications.

The valve's robust high-pressure valve system maintains consistent performance even under varying temperature extremes and physical stress, ensuring reliable lubrication when it matters most. Our specialized extreme-condition mechanism incorporates reinforced seals and heavy-duty components that resist wear, impact, and chemical degradation.

This industrial-strength dispensing solution features an oversized flow path and reinforced actuator designed for use with gloved hands, providing positive engagement even in wet or oily conditions. The valve's durable construction prevents failure due to vibration, impact, or exposure to harsh elements, making it the go-to choice for maintenance professionals working in challenging environments.

Key Features

- Heavy-duty WD-40 Lubricant Valve engineered for extreme industrial environments

- Advanced corrosion-resistant valve construction withstands harsh chemicals and weather

- Reliable high-pressure valve system maintains performance under demanding conditions

- Specialized extreme-condition mechanism resists wear, impact, and degradation

- Industrial-strength dispensing design ensures reliable operation with gloved hands

Application Scenario

At a mining site, maintenance crews need to lubricate heavy excavator components in dusty, wet conditions. Using our heavy-duty valve, they can effectively apply lubricant despite the challenging environment, with the corrosion-resistant construction preventing valve failure and the high-pressure system ensuring consistent flow even with cold, viscous lubricants in low-temperature conditions.

Factory Production Floor

Our manufacturing facility for heavy-duty valves features reinforced construction and specialized equipment designed for working with enhanced materials. The production line includes salt-spray testing chambers for corrosion-resistant valve validation and pressure cycling equipment that simulates years of service in extreme conditions.

Each valve undergoes impact testing and vibration analysis to ensure the extreme-condition mechanism can withstand real-world industrial abuse. Final assembly incorporates quality verification steps that exceed standard industry requirements for heavy-duty applications.

Packing and Transportation

Heavy-duty valves are packaged in industrial-grade containers designed to withstand rough handling during shipping to remote locations. They are packed in weather-resistant corrugated containers with reinforced edges and protective cushioning.

Shipping pallets are banded with steel strapping and covered with weatherproof wrapping to ensure products arrive in perfect condition, even when transported to sites with limited infrastructure.

Frequently Asked Questions

What specific environmental conditions is this heavy-duty WD-40 Lubricant Valve designed to withstand?

Our heavy-duty WD-40 Lubricant Valve is engineered to operate reliably in temperature extremes from -40°C to 80°C, high humidity, salt spray environments, and conditions with high particulate contamination.

How does the corrosion-resistant valve construction differ from standard valves?

The corrosion-resistant valve features stainless steel springs, special coating on mounting cups, and chemically resistant elastomers that provide superior protection against rust and chemical degradation.

What pressure range can the high-pressure valve system accommodate?

Our high-pressure valve system is tested and certified to perform consistently at pressures up to 15 bar while maintaining precise spray control and leak-free operation.

How does the extreme-condition mechanism enhance valve durability?

The extreme-condition mechanism incorporates multi-lip seals, reinforced housing geometry, and impact-resistant materials that collectively enhance valve life in demanding applications.

Can this valve be used with specialized industrial lubricants containing extreme pressure additives?

Yes, the valve materials are compatible with lubricants containing EP additives, anti-wear agents, and solid lubricants commonly used in heavy equipment maintenance applications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!