Precision-Engineered WD-40 Lubricant Valve for Industrial Maintenance and Machinery with Consistent Straw-Attached Spray Control

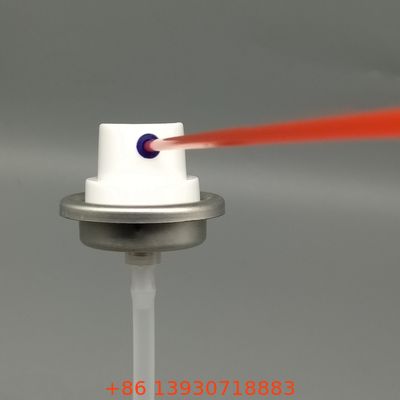

Introducing our high-performance WD-40 Lubricant Valve, a critical component engineered for the iconic penetrating oil and multi-use spray. This specialized aerosol lubricant valve is designed to deliver the precise, controlled application that professionals and industrial users rely on.

The valve's core is a robust dosing mechanism that ensures a consistent spray pattern, whether delivering a wide fan for coating large areas or a targeted stream through the integrated straw. This fluid control system is built to handle the specific viscosity and propellant pressure of WD-40 and similar lubricant formulations, preventing clogging and ensuring reliable performance from the first spray to the last.

Key Features

- Features a precision WD-40 Lubricant Valve for consistent, controlled application every time

- The integrated straw attachment point allows for targeted, pinpoint lubrication in hard-to-reach areas

- Robust internal dosing mechanism ensures reliable performance and complete canister evacuation

- Engineered for compatibility with the specific chemical composition of lubricant and penetrant formulas

- Durable construction prevents corrosion and extends the valve's functional life

Application Scenario

A maintenance technician in a manufacturing plant needs to silence a squeaky conveyor belt pulley. Using a can with our valve and the attached straw, they can precisely direct the lubricant onto the small bearing without overspray, quickly solving the problem without contaminating the surrounding belt or components.

Factory Production Floor

Our production of the WD-40 Lubricant Valve is a process of precision and quality. Automated assembly lines meticulously fit the spring, housing, and dip tube. Each valve is crimped into a mounting cup under tightly controlled parameters. A critical quality control stage involves automated testing of every valve's spray pattern and the functionality of the dosing mechanism to ensure it meets the stringent pressure and flow rate requirements for lubricant products.

Packing and Transportation

To ensure the valves arrive ready for high-speed filling lines, they are carefully packaged. They are often loaded into sealed plastic bags and placed in structured cardboard boxes or durable plastic crates that prevent deformation. These boxes are then stacked on pallets, securely wrapped, and shipped to our global partners, ensuring the spray dispensing assembly is protected during transit.

Frequently Asked Questions

Is your WD-40 Lubricant Valve compatible with all standard propellants used for lubricants?

Yes, our WD-40 Lubricant Valve is engineered and tested to perform reliably with the most common propellants used in lubricant and penetrant aerosol products.

How does the dosing mechanism prevent clogging from the viscous lubricant formula?

The dosing mechanism is designed with optimized fluid pathways and seal materials that resist the thickening effects of the lubricant, maintaining a clear passage for consistent spraying.

Can the straw be reliably attached to the aerosol lubricant valve during high-speed filling?

Absolutely. Our aerosol lubricant valve is designed for compatibility with automated straw attachment equipment, ensuring a secure fit on modern, high-speed filling production lines.

What measures are in place to test the reliability of the fluid control system?

Every fluid control system undergoes rigorous pressure decay testing and sample-based spray testing to verify leak-proof integrity and consistent operational performance before shipment.

Is the spray dispensing assembly resistant to the corrosive nature of certain penetrants?

Yes, the materials used in our spray dispensing assembly, including the housing, spring, and gaskets, are selected for their excellent resistance to corrosion and chemical degradation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!