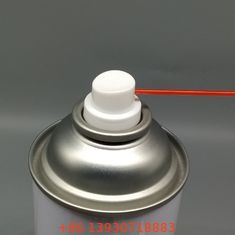

High-Capacity WD-40 Lubricant Valve for Manufacturing Facilities and Automotive Assembly Lines with Rapid-Dispensing Technology

Product Description

Engineered for maximum efficiency in high-volume settings, our industrial-grade WD-40 Lubricant Valve delivers unmatched performance for manufacturing and production environments. This robust high-volume valve system is specifically designed to meet the rigorous demands of assembly lines and maintenance departments where speed and reliability are crucial. The valve features an advanced industrial dispensing mechanism that ensures consistent flow rates even during continuous operation, preventing the downtime that plagues conventional valves. Its innovative rapid-release technology enables faster application times while maintaining precise control over spray patterns, significantly improving workplace efficiency. The heavy-duty production-grade valve construction withstands constant use and maintains perfect sealing integrity under high-frequency operation. For large-scale operations requiring reliable lubrication solutions, this high-capacity valve system offers the durability and performance needed to keep production moving smoothly. The specialized continuous-use mechanism incorporates heat-resistant components and reinforced seals that prevent failure even in demanding industrial conditions, making it the ideal choice for automotive plants, manufacturing facilities, and industrial maintenance teams that depend on consistent, reliable lubrication performance day after day.

Key Features

- Industrial-strength WD-40 Lubricant Valve built for high-frequency applications

- Advanced high-volume valve system ensures consistent performance under continuous use

- Efficient industrial dispensing mechanism prevents clogging and flow reduction

- Innovative rapid-release technology reduces application time while maintaining precision

- Durable production-grade valve construction withstands demanding industrial environments

Application Scenario

In an automotive assembly plant, workers need to quickly lubricate multiple door hinge points on vehicles moving along the production line. Using our high-capacity valve, they can complete each lubrication task in seconds with consistent coverage, keeping pace with the assembly line's speed while ensuring every hinge receives the proper amount of lubricant without overspray or dripping.

Factory Production Floor

Our manufacturing process for industrial-grade valves incorporates automated quality control systems that test each valve's performance under simulated high-volume conditions. The production line features precision robotics that assemble the reinforced components, with multiple inspection points verifying the industrial dispensing mechanism meets strict flow rate and pressure tolerance specifications. Each valve undergoes cycle testing to ensure the continuous-use mechanism can withstand thousands of actuations without performance degradation.

Packing and Transportation

Designed for industrial customers, these valves are packaged in bulk quantities with efficient space utilization. They are loaded into durable, returnable plastic containers that withstand rough handling in industrial settings. The containers are clearly labeled with product specifications and batch information, then securely palletized with protective corner guards for safe shipment to manufacturing facilities worldwide.

Frequently Asked Questions

What makes this WD-40 Lubricant Valve suitable for high-volume manufacturing environments?

Our WD-40 Lubricant Valve features reinforced internal components and specialized sealing technology designed to maintain consistent performance through thousands of cycles, making it ideal for high-volume industrial applications.

How does the high-volume valve system maintain consistent flow during continuous use?

The high-volume valve system incorporates precision-engineered fluid pathways and temperature-stable components that prevent flow reduction even during extended continuous operation.

Can the industrial dispensing mechanism handle different lubricant viscosities?

Yes, the industrial dispensing mechanism is calibrated to work effectively with various lubricant formulations, from light penetrating oils to heavier grease-based products commonly used in industrial settings.

What quality assurances support the production-grade valve durability claims?

Our production-grade valve undergoes rigorous testing including pressure cycling, thermal stress tests, and material compatibility verification to ensure it meets industrial performance standards.

How does the rapid-release technology improve application efficiency?

The rapid-release technology features optimized actuator mechanics that reduce operator fatigue while ensuring immediate flow initiation and cessation, significantly speeding up lubrication tasks in time-sensitive production environments.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!