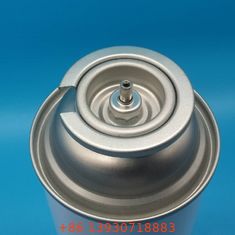

Advanced Medical-Grade Gas Canister Valve for Therapeutic Oxygen Cylinders with Pin-Index Safety System

Product Description:

The advanced medical-grade gas canister valve is a critically engineered flow control device designed exclusively for therapeutic oxygen cylinders used in medical and home healthcare settings. Constructed from 100% oxygen-compatible materials such as specialized brass and stainless steel, this cylinder valve is engineered to prevent combustion and ensure absolute purity of the gas stream. Its defining feature is the incorporation of the international Pin-Index Safety System (PISS), a safety mechanism that ensures the valve can only be connected to the correct oxygen regulator, preventing accidental connection to equipment meant for other medical gases. This precise gas regulation is paramount for patient safety, delivering the prescribed flow rate without fluctuation.

Manufactured in a certified cleanroom environment, the production process adheres to strict medical device regulations (such as ISO 13485). Every component is meticulously cleaned and passivated to remove any contaminants or particulates that could be hazardous to a patient. The valve outlet is machined to exacting tolerances to guarantee a perfect seal with the regulator. Each unit undergoes a helium leak test, a highly sensitive method that detects even the most minute leaks, ensuring the integrity of the cylinder from the factory to the patient's bedside. This valve is more than a component; it is a vital link in the chain of patient care, providing reliable and safe oxygen delivery for individuals managing respiratory conditions.

Bullet Points:

-

Pin-Index Safety Mechanism: Ensures connection only to the correct oxygen regulator, a critical safety feature for medical applications.

-

Precision Flow Control: Allows healthcare professionals to set and maintain accurate oxygen liter flow for patient therapy.

-

Oxygen-Compatible Materials: Manufactured with specialized materials to prevent fire risk and gas contamination.

-

Guaranteed Purity: Produced in a cleanroom and rigorously cleaned to ensure the medical-grade integrity of the oxygen.

-

Reliable Cylinder Valve: Built for durability and repeated use in both clinical and home environments, supporting long-term patient care.

Specific Application Scenario:

A patient with chronic obstructive pulmonary disease (COPD) uses a portable oxygen cylinder equipped with this valve at home. The home nurse connects a prescribed oxygen regulator to the valve's pin-index outlet, setting the exact flow rate needed for the patient's nebulizer treatment, ensuring safe and effective respiratory therapy.

Specifications:

| Component |

Part Description |

| 1. Mounting Cup |

(Portable gas stove valve) Special mounting cup |

| 2. Outer Gaske |

Buna |

| 3. Inner Gasket |

Buna |

| 4. Stem |

(Portable gas stove valve) Special stem |

| 5. Spring |

Stainless steel |

| 6. Housing |

(Portable gas stove valve) Special Housing |

Exhibition:

We often go to India, Mexico, Algeria for aerosol valve exhibitions. Our potable butane gas stove valves have been exported to Mexico, Ecuador, Viet Nam, India, Colombia, Russia, Ukraine, Indonesia, Peru, Philippines and other countries.

Strict quality control system (100% leaking test+ SGS check + QC check)

Short lead time ( 10 days for OEM )

Competive price

Customerize packing accepted

One-stop Service

Packing and Delivery

Carton size: 560*370*220mm

Gas valve: 1500 pieces / carton

Red cover: 2500 pieces / carton

We can export the portable gas stove valves to you by LCL container and full 20ft, 40ft, 40HC container. We can use carton packing and pallet packing.

FAQ:

-

What is the Pin-Index Safety System on this medical gas valve?

-

Why are specific materials required for this type of flow control device?

-

How is the purity of the gas ensured by the cylinder valve?

-

The valve is manufactured and cleaned in a controlled environment to remove all particulates, oils, and hydrocarbons. The integrity of the seal ensures no external contaminants can enter the cylinder after filling.

-

Can this valve be used for other medical gases like nitrous oxide?

-

What is the typical service life and maintenance requirement for this valve?

-

The valve itself is designed for the life of the cylinder. However, the cylinder must be hydrostatically tested every 5-10 years as per regulations, during which the valve is inspected and serviced or replaced by certified technicians.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!