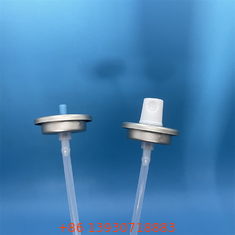

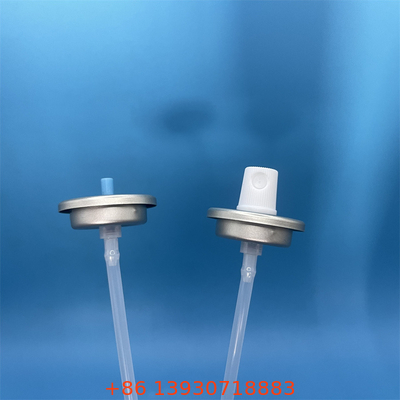

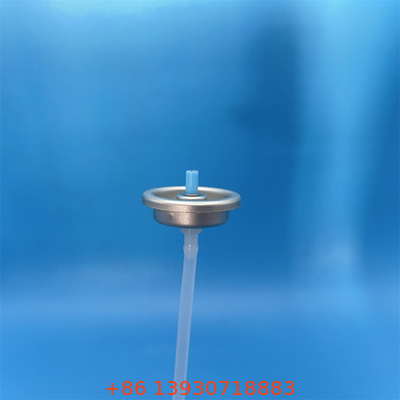

Robust Heavy-Duty MDF Kit Valve Activator for Industrial Solvents and Lubricants with Leak-Proof Sealing & Consistent Dosing

Product Description :

Engineered for demanding industrial environments, our MDF Kit Valve Activator forms the critical control point in reliable aerosol dispensing systems. This integral valve actuator component is specifically designed for challenging applications involving industrial solvents, degreasers, lubricants, adhesives, and coatings where chemical resistance and unwavering performance are paramount. It works seamlessly within the complete metering valve assembly to initiate a precise, controlled release of product upon user actuation. Built for durability, it features advanced leak-proof sealing technology at critical interfaces, preventing product loss, propellant escape, and potential safety hazards, even when handling aggressive formulations or operating under variable pressure conditions.

Manufactured from high-grade, chemically inert polymers and specialized elastomers, this actuator stem excels in harsh settings, resisting degradation from oils, solvents, and extreme temperatures. Its robust design ensures consistent performance batch after batch, delivering predictable spray patterns – from fine mists to targeted streams – essential for efficient application and minimizing waste. The ergonomic design prioritizes positive user feedback and comfortable operation, even with gloved hands common in workshops and factories. This dispensing trigger mechanism is the cornerstone of dependable industrial aerosol systems, guaranteeing that every press delivers the intended result, enhancing productivity, safety, and user trust in the most rigorous chemical and mechanical applications.

Bullet Points:

Features advanced leak-proof sealing technology for maximum safety and product integrity with aggressive chemicals.

Ensures consistent performance and reliable controlled release across diverse industrial formulations.

Constructed with premium chemically resistant materials for exceptional durability in harsh environments.

Robust valve actuator design built for high-cycle operation and dependable metering valve function.

Ergonomic actuator stem provides positive tactile feedback and comfortable operation.

Specific Application Scenario:

Imagine a maintenance technician in an automotive plant using a penetrating oil to free a seized bolt. They point the aerosol can, press down firmly on the MDF Kit Valve Activator. Instantly, a powerful, targeted stream of oil is delivered precisely where needed, demonstrating consistent performance and controlled release. The leak-proof sealing ensures no solvent fumes escape during storage or after use, maintaining workshop air quality and safety even when the can is stored on its side in a toolbox.

FAQ:

Q1: Is this MDF Kit Valve Activator compatible with chlorinated solvents found in heavy-duty degreasers?

A1: Yes, specific variants utilize highly chemical-resistant elastomers (e.g., FKM/Viton) within the metering valve assembly to ensure leak-proof sealing and material integrity.

Q2: How does the valve actuator maintain consistent performance under high-vibration conditions common in industrial settings?

A2: The robust design, precise spring tolerances, and secure internal locking mechanisms ensure reliable controlled release and prevent malfunction due to vibration.

Q3: Can the actuator stem withstand repeated impacts if the aerosol can is dropped?

A3: Our industrial-grade actuator stem is made from impact-modified polymers designed to resist cracking or breaking under typical accidental impacts, protecting the metering valve integrity.

Q4: What is the maximum operating pressure this dispensing trigger mechanism is rated for?

A4: Standard kits are rated for common aerosol pressures (e.g., up to 10 bar/145 psi at 50°C). Higher-pressure variants are available; consult specifications for your application.

Q5: Does the design prevent clogging of the metering valve orifice with viscous lubricants?

A5: The controlled release pathway and actuator design minimize dead space and promote positive shut-off, reducing the risk of clogging. Compatibility testing with specific viscosities is recommended.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!